Enfield Clock History

The following by Mr. C.J. Prior-Clarke outline the history and development of The Enfield Clock Factory, the sister establishment to the Anglo-Celtic Watch Company which shared its Ynyscedwyn location.

In July 1948, the centre reservation between the two factories was made ready for the receipt of stores etc. Mr F. Kienzler took up residence, employing two store men (Jack Morgan and Rhys Evans).

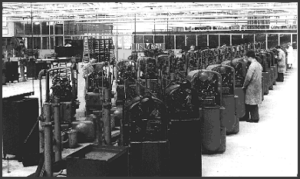

On the 24th January 1949 the main part of the Enfield Factory opened for the assembly and part manufacture of the F3 striking clock. 1949 saw the consolidation of manufacturing such as autos, gear cutting, and machine shop operation, together with the introduction of bezel manufacture which incorporated plating and polishing and metal finishing techniques.

A factory established

1950-52

This period was engaged in manufacturing striking clocks, including pendulum time pieces, and the casing of strikes and time pieces, i.e. kitchen clocks and Bakelite cased strikes, BimBams etc.

1952 saw the introduction of the 8 day conical pivot QH movement. The escapement itself was manufactured and assembled at the No.1 factory, Enfield works, Edmonton. After a period of about 1 year this movement was transferred to London and was lost in oblivion.

New Developments

Change in the movement

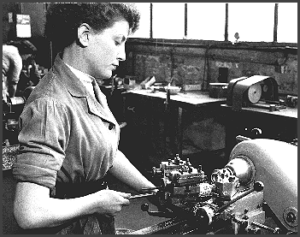

During the period 1949-52 the F3 movement was made shallower. It was reduced by 10mm and became known as the F7 movement. On the time timepiece side, the same depth of movement was also reduced to incorporate a new plastic kitchen clock named the Torre.

A new role for the Gurnos works

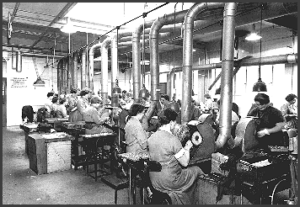

Early in 1953 the No.1 factory at Edmonton was closed and the whole of the manufacture and work involved was transferred to Ystradgynlais. At the same time the Mingware Company which manufactured watch cases, medals and medallions was also transferred from Dundee. From 1953 onward, therefore, the development of the watch case took place culminating in large production of solid watch cases with their diamond turned techniques, both chromium plated and gold plated for the use of the neighboring Anglo-Celtic Watch Company.

This period also saw the development of new processes such as gong manufacture, incorporating tuning rods and its associated techniques.

During this period of watch case development, the gold plating techniques were introduced together with the anodizing of aluminum watch cases.

Expanding product

Balance movements

The period 1954-1955 was one of principal involvement in the development of the floating balance movement which was a unique departure from the orthodox horological practices. This movement was first developed as the F6 and was eventually also developed in respect of the K6 chime movement which had been manufactured from 1953 onwards at Ystradgynlais. The floating balance chime movement was known as the K7.

Variations of the K6 and K7 were also developed and manufactured on the site which were the Westminster/Whittington version and included amplified gong which was a unique gong attached to the base of the movement operated by an under-slung hammer arrangement of considerably reduced dimensions.

1956

The QTA travel alarm which had been developed in London was introduced and manufactured at Ystradgynlais. This was produced in many guises besides travel alarms, such as roller shutter, and brass cases, musical box etc. During this period the Anglo-Celtic wind movement was also purchased and assembled to a Mazac casing with polished base, and known as the Elfin.

1956-57

This period saw the introduction of the manufacture of gold cases, which was of course a unique technique in as much as it was the company’s first experience of working in precious metals. Also during this period the old gold plating technique was superseded by a better process which utilized gold salts and made it possible to control the gold deposit for both the more expensive Cheltenham watches and the less expensive locally produced watches at the sister plant.

Diversification

1957-66

Mr. Ray Smith at a staff function in the 1950s. (third row back, third from the right)

This was a period of development of the company’s existing products. The travel alarm was firstly reduced in depth and known as the QTC. It was then further developed as a single wind alarm known as the QTD.

This period also saw the introduction of the Gasoset. An embryo form of gasoset was provided for us by the Brighton factory but this was extensively developed on the site by the late R.L. Smith, and was produced in good numbers and in many guises for a number of gas companies.

During these nine years we also produced a number of mechanically operated electric time switches accommodating various sub-functions. The now defunct Pathe 10mm camera was manufactured on site. This camera was pushed out by the up-and-coming 8mm camera apparently is capable of using both sides of the film.

Also at this time was the famous – or perhaps infamous – “Fum-a-dor”. This somewhat weird instrument produced a spray of sweet or ill smelling vapor into the room.

Ship Your Clock for Expert Repairs!

Expert Shipping Instructions!

Grandfather Clock Service Calls

We make Grandfather Clock service calls!

Contact Us

Feel free to contact us any time at (215) 862-2415.

Further Questions?

We'd like to hear from you!

People Say